42580 Rio Nedo Rd Temecula, CA 92590

42580 Rio Nedo Rd Temecula, CA 92590

Toll Free: +1 800 207 4804

Telephone: +1 951 296 6585

FAX: +1 951 296 5018

E-mail: sales@resina.com

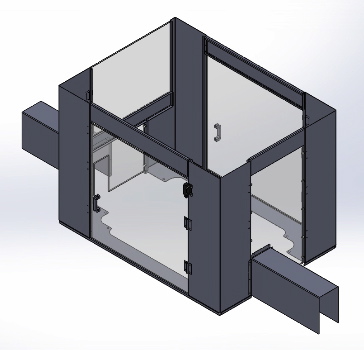

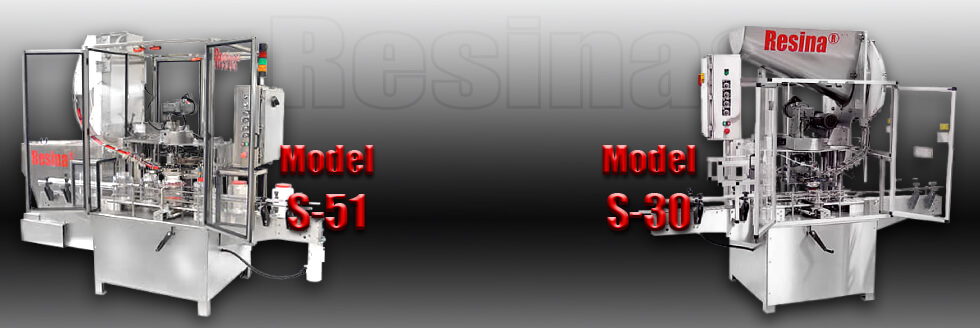

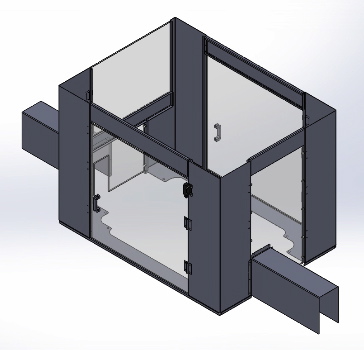

All new Resina Capping Machines come with complete OSHA standardized electronically interlocked enclosures to promote the safety of your packaging plant, however, many older cappers may not follow these safety standards. If your plant currently owns a capping machine, lidding machine, or fitment machine which is not safety guarded, we urge you to upgrade or add an enclosure as required by current OSHA regulations. This is essential towards maintaining a safe work environment at your plant, protecting the individuals on your packaging floor, and defending against product contamination.

The applicable OSHA machine safety guarding specs are as follows:

1917.151(a)

"Definition. "Guarded" means shielded, fenced, or enclosed by covers, casings, shields, troughs, spillways or railings, or guarded by position or location. Examples of guarding methods are guarding by location (positioning hazards so they are inaccessible to employees) and point of operation guarding (using barrier guards, two-handtripping devices, electronic safety devices, or other such devices)."

1917.151(b)(4)

"A power cut-off device for machinery and equipment shall be provided at the operator's working position."

1917.151(b)(7)

"The power supply to machines shall be turned off, locked out, and tagged out during repair, adjustment, or servicing."

If your company's capping machine is not compliant with these specifications, we urge you to add or upgrade your capper's safety gaurding system. All of our safety enclosures are made here in the USA.